Leak Detectors

Reset the filters to get results.

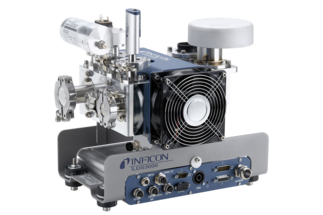

With the ELT3000 PLUS Battery Electrolyte Leak Detector, INFICON offers a unique, non-destructive leak testing solution for all Lithium-ion battery cells, including fragile pouch cells.

- Direct electrolyte leak testing of all lithium and sodium-ion battery formats

- Unmatched measurement reliability - no leak is missed

- Maximum efficiency with multi-chamber connection for the targeted throughput

- Quality assurance and longevity due to high sensitivity

Specifically designed for full-time sniffing applications in demanding production Environments.

- I-Guide operator guiding mode ensures your operator is testing the right locations with the correct technique.

- Improved system design compensates for operator error reducing the potential for missed leaks.

- Multiple alarm functions make sure alarms can not be overlooked.

- Built-in PRO-Check reference leak allows for easy and fast calibration at the production line at any time.

HIGH FLOW technology for highest measurement certainty and fastest throughput.

- INFICON High Flow Technology

- Enables unmatched measurement certainty - stop missing leaks!

- Finds leaks even in hard to access areas

- Helps unexperienced operators to reliably locate leaks

Modern leak detector for industrial use

- Handles both small and large leaks, quick reaction - fast recovery, even after large leaks

- Highly sensitive and selective hydrogen sensor - incorporates proven Sensistor sensor technology

- Can detect and locate leaks with a size variation within ten decades

- New color touchscreen and new HMI for easy, more reliable menu navigation

The portable Extrima Leak Detector is the ultimate intrinsically safe instrument for leak detection in the toughest environments, including hazardous locations such as Zone 0.

- Intrinsically safe for use in hazardous areas (Ex ia IIC T3)

- Up to 7 hours battery operating time -Robust enclosure for demanding field use

- High sensitivity and fast recovery allow for efficient operation

- Low and easy maintenance

Fast, reliable and robust instrument for utilities leak detection such as telecom cables and water pipes

- Quick detection through high and adjustable sensitivity

- Highly selective hydrogen sensor for reliable detection

- Easy to carry and handle

- Quick charging in the car (5 minutes for 20 minutes of operation)

New levels of productivity and reliability to the final leak testing of refrigerators, freezers, automotive air conditoners and similar products.

- Improved system design compensates for poor sniffing operation reducing the potential for missed leaks.

- IGS (Interfering Gas Suppression) ensures only leaks are detected.

- Built-in ECO-Check reference leak allows for easy and fast calibration at the production line at any time.

- Multiple alarms make sure leaks can not be overlooked.

User-friendly handling, reproducibility of measuring results and integration into local networks

- Compact, Light And Slim

- Touchscreen Display

- Communicative Diversity

- High Reliability

The ultimate in mobile vacuum leak detection designed to meet the most critical and demanding leak detection applications and in particular large volumes

- Fastest mobile vacuuum leak detector

- Most reliable leak detection

- Most robust vacuum system

- Slim & easy to manouver

- Intuitive control & Easy to use

Designed for the needs of leak checking in semiconductor applications

- Save Time with I·CAL software algorithm for fast measurements in the range of 10-9 to 10-12 mbar·l/s

- Most efficient leak checking using I·ZERO 2.0 with improved intelligent function for fast background suppression while maintaining high measurement sensitivity

- Applicable for vacuum and sniffer leak search

- Minimize leak checking efforts through quick evacuation and response time

renowned standard when it comes to economic helium vacuum leak testing in industrial or semiconductor environments

- minimize leak testing efforts through quick pump down and response time

- avoid need for multiple leak tests by using selectable background suppression (iZERO)

- enable easy access to maintenance areas with restricted space through maneuverable design

- low total cost of ownership (TCO) enabled by robust two hot filament ion source (3 years warranty) and counterflow vacuum system

Providing fast, accurate and repeatable test results, testing flexibility, and high sensitivity in a low maintenance design

- Wide measurement range over 15 decades

- Short pumpdown and response time

- Mobile all-metal housing for added convenience with uncompromised maneuverability

- I-CAL (Intelligent Calculation Algorithm for Leak rates)to ensure fastest response time to leaks in all measurement ranges

Modular leak detector, compact Performance at the Highest Level

- More Compact And Easier To Integrate

- Communicative Diversity

- High Reliability

Reliable, intelligent and repeatable platform, Optimize your production

- Reliable for maximum uptime

- Intelligent Design improves measurement certainty

- Easy setting of automated procedures

T-Guard2 Leak Detection Sensor closes the gap between costly hard vacuum helium leak detection and low sensitivity leak testing methods like waterbath and pressure decay.

- Low operating cost

- No limitation of product properties

- Find all leaks reliably

- Easy to use

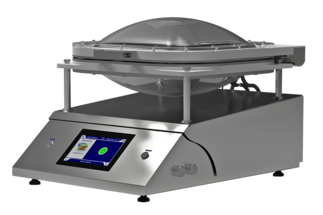

Cost efficient forming gas or helium for accumulation leak testing, very sensitive and can detect leaks down to the 10-5 mbar∙l/s range

- Cost efficient solution to leak test parts

- Testing as reliable as vacuum chamber - at nearly the cost of air testing

- Ready for the future with fieldbus interfaces for the Industry 4.0 integration

- Temperature and humidty indipendency offers reliable test results with high repeteability

This accessory to Sensistor Sentrac Hydrogen Leak Detector allows you to do automatic leak testing with hydrogen tracer gas

- High reliability for demanding industrial applications

- For semi- or fully automatic leak testing

- Easy to maintain

- Easy sensor change

Innovation makes the difference

- Distinction between natural gas and marsh gas with GC and IR-sensor

- No false alarms, high sensitivity, quick reaction and short recovery time thanks to the integrated proprietary IR-sensor system

- Weatherproof IP54

- Measurements possible even in tough environments thanks to its robust housing

Sustainable and reliable solution for seal inspection in Capsules, MAP- and other types of packaging.

- Be guaranteed to maximize your shelf life

- Avoid customer complaints and disstatisfaction

- Reduce product returns, save money and produce sustainably

- Improve your quality control process

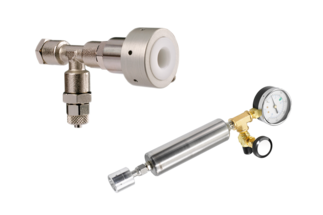

Tracer gas filler with complete tooling and gas filling functions

- Complete tooling and gas filling function for high-quality leak detection

- Eliminates the need for time-consuming manual tracer gas filling

- Less operator dependence - full control over all test steps

- Significantly improves test quality assurance

Tracer Gas Filler is a stand-alone instrument which allows for easy and reliable tracer gas filling and evacuating

- Ensured tracer gas filling in the entire test object

- Avoids background contamination

- Made for demanding industrial environments

- Dual port for filling and evacuating for short cycle times

Accessory to the Extrima, Ex-certified Hydrogen Leak detector, for injecting tracer gas into fuel leaks during maintenance of aircrafts

- Makes back tracing aircraft fuel leaks controlled and efficient

- Can be operated by one operator

- Includes all you need between the tracer gas bottle and the leak

- Helps keep your detector calibrated

Enable to test and to calibrate the Helium sniffer leak detector Protec P3000(XL) and XL3000flex for the highest quality demands in leak detection

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

Calibrated test leaks enable to test and to calibrate refrigerant sniffer leak detectors for the highest quality demands in leak detection

- Easy to use

- Suitable for industrial applications

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

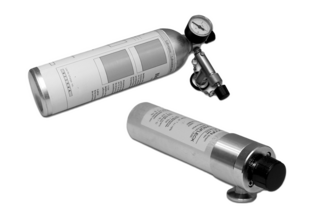

Calibration test leaks with gas reservoir for vacuum applications

- Inured to pollution

- Metal-free flow reduction for low temperature dependences

- Detemination of the nominal leak rate by comparison with a calibrated leak having a PTB certificate

- Inspection certificate ( included ) in accordance to DIN EN 10204:2004-3-3.1

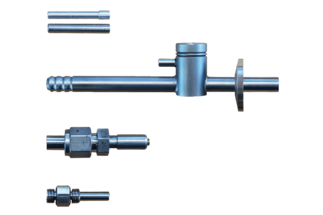

Calibrated leaks which are capable of meeting the requirements concerning type and required leak rate

- Various types adapted to different customer requirements

- Simple to operate

- Easy to install

- Ideal installations dimensions

Calibrated test leaks enable to test and to calibrate refrigerant sniffer leak detectors for the highest quality demands in leak detection

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

Cover a wide range of leak rates to suit your specific application and include bigger leaks (Types A-C) and smaller leaks (Types E and G). Leak Type A is intended for accumulation testing only

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Traceable to NIST, NMIJ, NPL, PTB, etc.

Superior sensitivity and interchangeable sensors for maximum versatility.

- New, redesigned infrared sensor with easy field replacement

- Quick charge lithium ion battery

- Detects CFCs, HCFCs, HFCs, HFOs, blends (including A2Ls), CO2*, and flammables*

Cloud hunting PPM display, superior sensitivity, and interchangeable sensors for maximum versatility.

- Innovative cloud hunter mode with ppm helps locate leaks faster than ever

- New, redesigned infrared sensor with easy field replacement

- Quick charge lithium ion battery

- Detects CFCs, HCFCs, HFCs, HFOs, blends (including A2Ls), CO2*, and flammables*

Large, easy-to-read LCD display can not only pinpoint the leak location, but help quantify the leak size using the PPM reading.

- Detects R134a, R1234yf, and all HFCs, HFOs, and blends

- Meets all SAE standards for automotive AC leak detection

- Infrared sensor minimizes false alarms from common under-hood chemicals

- PPM and pinpoint modes help find leaks faster

Heated diode sensor for fewer false alarms with rechargeable convenience.

- Heated diode sensor provides excellent sensitivity

- Detects CFCs, HCFCs, HFCs, HFOs, and blends (including A2Ls)

- Rechargeable battery

- Easy one button operation

Easy operation and heated diode sensor for fewer false alarms.

- Heated diode sensor provides excellent sensitivity

- Detects CFCs, HCFCs, HFCs, HFOs, and blends (including A2Ls)

- Runs on two D-cell batteries

- Easy one button operation

Infrared sensor for fewer false alarms and superior sensitivity.

- Detects R-134a, R-1234yf, and all HFCs, HFOs, and blends

- Meets all SAE standards for automotive AC leak detection

- Infrared sensor minimizes false alarms from common under-hood chemicals

- Compatible with optional CO2 sensor

Simple operation and proven heated diode sensor for reliable leak checking.

- Sensitivity of 2 g/a (per EN 14624)

- Detects R134a, R1234yf, and all HFCs, HFOs, and blends

- Fewer false alarms than standard automotive leak detectors

- Runs on two D-cell batteries

Safe and easy leak checking using hydrogen forming gas.

- Detects forming and combustible gases

- 7 g (0.25 oz.)/year sensitivity to forming gas (R134a equivalent)

- Intrinsically safe

- Runs on two D-cell batteries

Compact reference leak source that continuously leaks R134a, R1234yf, or R600a refrigerant for over 2 years

- Available for R134a, R1234yf, or R600a

- Compact size easily fits in your leak detector carrying case

- Easy-to-use

- No batteries required

Simple, reliable and safe solutions for standalone constant monitoring of larger areas for most refrigerant gases.

- Detects all CFCs, HFCs, HCFCs, and HFOs

- Works with up to 6 remote sensors

- Low maintenance, single point calibration

- Three adjustable alarm setpoints

Simple, reliable and safe solutions for standalone constant monitoring of any refrigerant gas.

- Detects all CFCs, HFCs, HCFCs, HFOs, HCs, and CO2

- Remote and integrated sensor options

- Low maintenance, single point calibrations

- Three adjustable alarm setpoints

Versatility and flexibility for a variety of applications.

- Verstility for a variety of applications and industries

- Works on any gas under pressure or vacuum

- Hear the leak using the included headphones

- Laser pointer makes it easier to pinpoint the leak

Safely detect flammable refrigerant and combustible gas leaks.

- Sensitive to 5 ppm methane

- Also detects natural gas, forming gas, propane, butane, cyclopentane, ethane, ethanol, isobutane and ammonia

- Great for flammable refrigerants like R290, R600a, and R441a!

- Detects forming gas (95% nitrogen, 5% hydrogen)

Convenient and simple operating for easy detection of carbon monoxide hazards.

- Best-in-class accuracy for peace of mind

- Simple operation lets you perform all functions with one hand

- Highly visible, intuitive "stoplight" LEDs and audible alarm give you quick indication of CO hazard

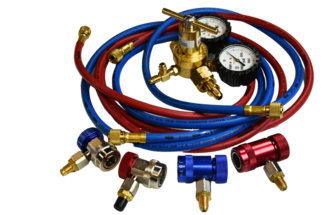

Economical leak detection without the loss of expensive refrigerant.

- Leak check with environmentally friendly N2H2

- Couplers for both R1234yf and R134a systems

- Charges both high and low side of the AC system

Inline leak testing for the mass production of battery cells

- Inline leak testing for the mass production of battery cells

- Direct electrolyte leak testing of all metal-ion battery formats

- Unmatched measurement reliability - no leak is missed

- Easy integration into high-speed production systems

- Maximum efficiency with multi chamber connection for the targeted throughput

I-Guide3D 350 Scanner: Maximum Precision for Fully Automated Leak Test Systems

- Automize manual sniffing process regardless variances of joints

- For all tube sizes starting from 1,5mm

- Robot path planning done by software to optimize cycle time

- Become less dependant from workers